Dhuwur Alumina Refractory Castable

Informasi produk

| Jeneng produk | Refractory Castable |

| Kategori | Castable Semen Low/Dhuwur Kekuwatan Castable/Dhuwur Alumina Castable / Castable entheng |

| Komposisi | Agregat refraktori, bubuk lan pengikat |

| Fitur | 1. Gampang Konstruksi, 2. Tahan Slag apik, 3. Good Corrosion Resistance, 4. Good Fire Resistance, 5. Ngirit Energi lan Perlindhungan Lingkungan. |

| Aplikasi | Digunakake kanthi akeh ing macem-macem tungku industri suhu dhuwur. |

| Produk | Low Cement Castable | Dhuwur Strength Castable |

| Katrangan | Castables semen kurang nuduhake castables anyar karo Binder semen banget sethitik.Isi semen saka castables refractory umume 15% kanggo 20%, lan isi semen saka castables semen kurang kira 5%, lan sawetara malah suda kanggo 1% kanggo 2%. | Castable tahan nyandhang kekuatan dhuwur kasusun saka agregat kekuatan dhuwur, admixtures mineral, agregat kekuatan dhuwur lan anti crack lan agen tahan nyandhang. |

| Fitur | Ketahanan kejut termal, resistensi slag, lan resistensi erosi tambah akeh, ngluwihi bata tahan api sing padha. | Kekuwatan dhuwur, resistance nyandhang dhuwur, resistance impact, resistance erosi, permeabilitas anti-lenga, kontrol wangun sembarang, integritas kuwat, construction prasaja, kinerja construction apik, lan layanan dawa. |

| Aplikasi | 1.Lining macem-macem tungku perawatan panas, tungku pemanasan, kiln poros, kiln rotary, tutup tungku listrik, tapholes tungku jeblugan; 2. Self-mili castables semen kurang cocok kanggo suhu dhuwur semprotan bedhil linings kanggo metalurgi semprotan lan petrokimia catalytic cracking reaktor Wear-tahan lining, lining njaba saka tungku panas pipe digawe adhem banyu, etc. | Lapisan lapisan slag sing tahan aus,palung bijih, spout batu bara, hopper lan silo ing metalurgi, batu bara, daya termal, kimia,semen lan industri liyane, lan blast furnace nyawiji silo, sintering silo, feeder, pelletizer, etc. |

| Produk | Dhuwur Alumina Castable | Castable entheng |

| Katrangan | Castables dhuwur-alumina sing refractorycastables digawe saka bahan mentahan dhuwur-aluminaminangka agregat lan bubuk, lan ditambahakekaro binders. | Castable entheng karo Kapadhetan akeh kurang digawe saka semen aluminate, bahan alus alumina dhuwur, ceramsite, lan aditif. |

| Fitur | Nduweni kekuatan mekanik sing dhuwur lan tahan kejut termal sing apik, tahan abrasi lan sifat liyane. | Kapadhetan akeh sing kurang, konduktivitas termal cilik, efek insulasi termal sing apik, kekuatan tekan dhuwur, tahan karat asam lan gas asam, insulasi panas, insulasi termal, lan panyerepan banyu sing kurang. |

| Aplikasi | Utamane digunakake minangka lapisan jero boiler, tungku jeblugan kompor jeblugan panas, tungku pemanasan, kiln keramik lan kiln liyane. | Castable entheng bisa digunakake kanggo lapisan insulasi termal tungku industri suhu dhuwur lan peralatan uga digunakake kanggo lapisan macem-macem pipa gas suhu dhuwur. |

Indeks produk

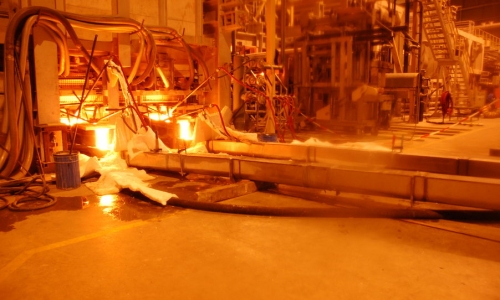

Kompor Blast Panas

Tunnel Kiln

Rotary Kiln

Industri wesi lan baja: utamane digunakake kanggo pangopènan lan patching tungku busur listrik, tungku baja, ladle lan peralatan liyane.

Industri logam non-ferrous: digunakake kanggo nambal lan ndandani tembaga, aluminium, seng, nikel lan tungku peleburan logam non-ferrous liyane lan konverter.

Industri kaca: digunakake kanggo pangopènan lan karya patch tungku kaca, tungku annealing lan peralatan liyane.

| Jeneng produk | Low Cement Castable | |||||

| INDEKS | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Suhu Limit Kerja | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Kapadhetan Massal (g/cm3)110 ℃ × 24 jam ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Kekuwatan Bending Dingin110 ℃×24h(MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Kekuwatan Ngremuk Dingin (MPa) ≥ | 110 ℃ × 24 jam | 25 | 30 | 35 | 35 | 40 |

| CT ℃ × 3 jam | 50 1300 ℃ × 3 jam | 55 1350 ℃ × 3 jam | 60 1400 ℃ × 3 jam | 40 1400 ℃ × 3 jam | 70 1400 ℃ × 3 jam | |

| Pangowahan Linear Permanen@CT ℃×3h(%) | -0,5~+0,5 1300 ℃ | -0,5~+0,5 1350 ℃ | 0~+0.8 1400 ℃ | 0~+0.8 1400 ℃ | 0~+1.0 1400 ℃ | |

| Tahan Kejut Termal (1000 ℃ banyu) ≥ | — | — | — | 20 | — | |

| Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Jeneng produk | Dhuwur Strength Castable | |||||

| INDEKS | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Suhu watesan kerja (℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110 ℃ Kapadhetan Massal (g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modulus Pecah (MPa) ≥ | 110 ℃ × 24 jam | 6 | 8 | 8 | 8.5 | 10 |

| 1100 ℃ × 3 jam | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400 ℃ × 3 jam | 8,5 1300 ℃ × 3 jam | 9 | 9.5 | 10 | 15 | |

| Kekuwatan Ngremuk Dingin (MPa) ≥ | 110 ℃ × 24 jam | 35 | 40 | 40 | 45 | 60 |

| 1100 ℃ × 3 jam | 40 | 50 | 45 | 50 | 70 | |

| 1400 ℃ × 3 jam | 45 1300 ℃ × 3 jam | 55 | 50 | 55 | 100 | |

| Owah-owahan Linier Permanen(%) | 1100 ℃ × 3 jam | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400 ℃ × 3 jam | -0,45 1300 ℃ × 3 jam | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

| Jeneng produk | Dhuwur Alumina Castable | ||||||

| INDEKS | Al2O3(%)≥ | CaO(%) ≥ | Refractoriness (℃) | CT ℃×3h PLC ≤1% | 110 ℃ Sawise Pangatusan (MPa) | ||

| CCS | MOR | ||||||

| Clay Bonded | NL-45 | 45 | — | 1700 | 1350 | 8 | 1 |

| NL-60 | 60 | — | 1720 | 1400 | 9 | 1.5 | |

| NL-70 | 70 | — | 1760 | 1450 | 10 | 2 | |

| Cement Bonded | GL-42 | 42 | — | 1640 | 1350 | 25 | 3.5 |

| GL-50 | 50 | — | 1660 | 1400 | 30 | 4 | |

| GL-60 | 60 | — | 1700 | 1400 | 30 | 4 | |

| GL-70 | 70 | — | 1720 | 1450 | 35 | 5 | |

| GL-85 | 85 | — | 1780 | 1500 | 35 | 5 | |

| Low Cement Bonded | DL-60 | 60 | 2.5 | 1740 | 1500 | 30 | 5 |

| DL-80 | 80 | 2.5 | 1780 | 1500 | 40 | 6 | |

| Ikatan Fosfat | LL-45 | 45 | — | 1700 | 1350 | 20 | 3.5 |

| LL-60 | 60 | — | 1740 | 1450 | 25 | 4 | |

| LL-75 | 75 | — | 1780 | 1500 | 30 | 5 | |

| Sodium Silikat Bonded | BL-40 | 40 | — | — | 1000 | 20 | — |

| Jeneng produk | Castable entheng | ||||||

| Suhu watesan kerja | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110 ℃ Kapadhetan Massal (g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus Pecah (MPa) ≥ | 110 ℃ × 24 jam | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100 ℃ × 3 jam | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400 ℃ × 3 jam | — | — | 3 | 10.8 | 8.1 | ||

| Kakuwatan Dingin (MPa) ≥ | 110 ℃ × 24 jam | 8 | 8 | 11 | 12 | 10 | |

| 1100 ℃ × 3 jam | 4 | 4 | 5 | 11 | 10 | ||

| 1400 ℃ × 3 jam | — | — | 15 | 22 | 14 | ||

| Owah-owahan Linier Permanen(%) | 1100 ℃ × 3 jam | -0,65 1000 ℃ × 3 jam | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400 ℃ × 3 jam | — | — | -0.8 | -0.55 | -0.45 | ||

| Konduktivitas termal (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Aplikasi

Paket & Gudang